Businesses have been reeling from the effects of COVID-19. Governments all over the world have shut down or issued directives to stay at home, creating large-scale disruptions in everyday life.

In Singapore, the Circuit Breaker and Work From Home directives have forced many businesses to drastically pivot their strategies. Others have had to cut back to skeleton crews just to stay afloat.

Some businesses have supply chains that depend heavily on vendors from China. In these cases, cracks in the supply chain have already been appearing since mid-January 2020. Most other businesses have since been affected, either through the trickle-down effect or due to the restrictions put into place to battle the virus.

Global supply chains have exposed their weaknesses as businesses try to come as close to ‘business as usual’ as possible. For those businesses with agile supply chains, a quick pivot can help to stay afloat, but others will need a lot more help to weather this storm.

The Importance Of An Agile Supply Chain

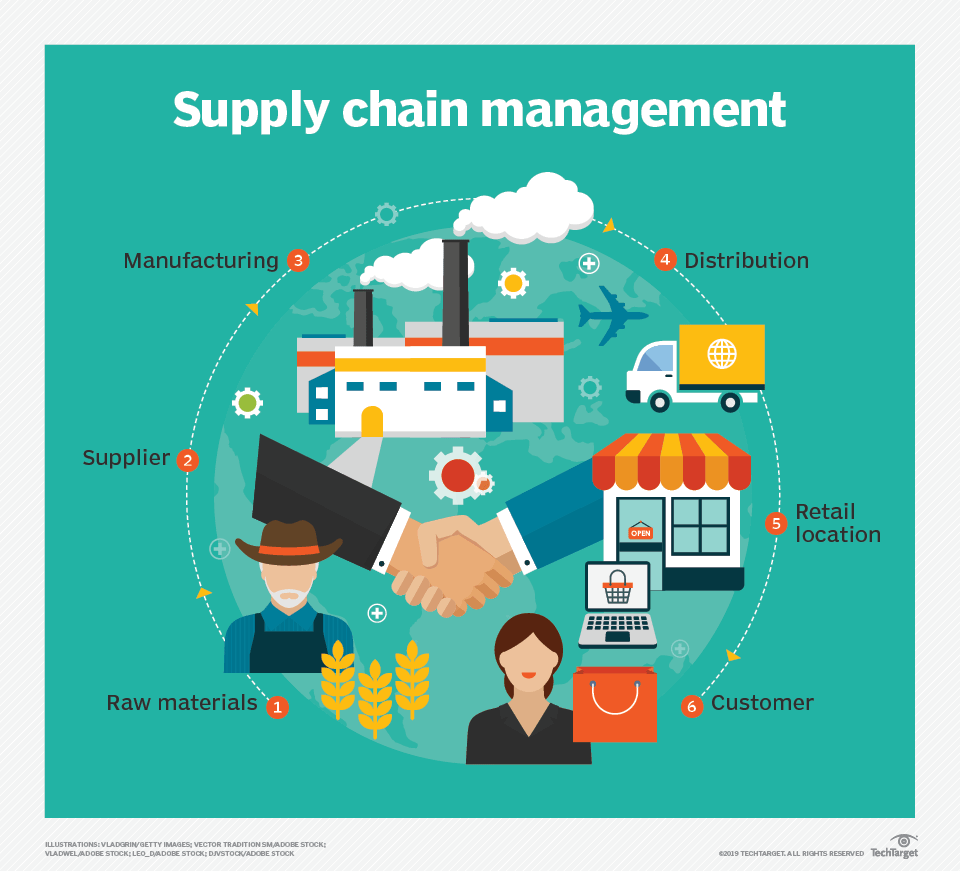

Source: SearchERP

Data is the driving force behind keeping a business on time and responsive to change. From inventory stock to manufacturing processes and delivery times, businesses need the most up-to-date data to plan for maximum efficiency.

Being flexible and responsive to rapid changes in market demand is the definition of an agile supply chain. Yet in these times, what we’ve seen is a lack of such agility in the supply chains of many businesses.

Agile supply chains depend on real-time data to ensure that risk management is kept low. Forecasting is made with accurate predictive data, and assets are kept with maximum flexibility. A study by McKinsey back in 2015 showed that agile companies were in the top 70 to 76 quartile for areas such as inventory placement, integrated planning, and more.

This doesn’t mean that your business is doomed to fail if it currently lacks an agile supply chain. By learning to embrace alternative suppliers and business models, you can build agility into the supply chain of your business.

Proven Methods To Manage Supply Chain Disruptions

Following best practices for an agile supply chain can keep your business resilient against sudden change. While it takes time and effort to put in place all these improvements, we believe that the benefits outweigh the disadvantages.

Here are some proven methods for supply chain management:

1. Use Real-Time Data To Efficiently Track Processes

First things first: Make sure your data is up to date. With the constantly-changing landscape of business during COVID-19, data that is a month (or even just two weeks!) late can have negative repercussions throughout the business.

Manual reporting can be tough to collate frequently, so software that can provide real-time reports would be best. This reduces the amount of time needed for manual data collection, while increasing your ability to make informed decisions.

2. Keep Strong Supplier Networks Worldwide

Businesses have found that supplier networks extend beyond your primary vendor. Even if your supplier isn’t China-based, for example, your supplier’s vendor for raw materials might be. This snowballs into an issue that will require your attention.

Maintain relationships with suppliers and vendors worldwide, so that alternatives can be easily sourced when needed.

3. Make Sure You Have A Buffer

Keeping some inventory stock as a buffer is always going to be a plus, as is planning logistics and delivery schedules in advance.

Of course, this doesn’t mean you should keep overflowing stock. Using real-time data, an agile supply chain can produce the optimal amount of inventory that will maximise efficiency and productivity while maintaining your buffer.

4. Monitor Everything From Beginning To End

If you implement a software that provides real-time data and forecasting, a monitoring mechanism will also be needed. Companies that don’t close the gap from order to delivery end up with inaccurate data.

The Effect Of ERP Software on Supply Chain Management

Oracle-NetSuite ERP Interface

Oracle-NetSuite ERP Interface

Supply Chain management will only get more important over the next few years. As businesses recover after COVID-19, they will need to put in place agile supply chain practices. This will involve collecting and making use of real-time data, and expanding supplier networks. Constant monitoring of every aspect of the business and being flexible and responsive will be key.

Visibility into the operations of your business can make a big difference in results. Some research has shown that ERP software assists in providing a standardised view of business processes. ERP software has also been proven to improve information flow throughout the company, and can enhance collaboration with suppliers.

While ERP solutions differ significantly across providers, with different add-ons and integrations required for specific industries, your business can benefit from implementing an ERP software to help you build an agile supply chain to prepare for future disruptions.

Here are a few examples of how an ERP software can help you do so:

- One issue can easily snowball into a catastrophe during a global pandemic or a similar "black swan" event. ERP software solutions are often used to provide visibility throughout the entire supply chain. This reduces the chances of widespread shutdown, as business owners can quickly find the point of disruption and compensate for it.

- A delay in one segment of the supply chain can easily cause delays down the line. An ERP software condenses and simplifies process monitoring and management, which allows for detailed order tracking. This helps you keep track of your delivery schedules, inventory, Bill of Materials (BOM), and more.

- Inventory management throughout the supply chain has always been a complex logistical undertaking. An ERP solution can include a comprehensive inventory tracking system. This will keep up-to-date information on available stocks of raw material and end products.

- ERP software can help you maintain an updated pre-approved supplier list that can be activated at any time. This allows your business to quickly switch suppliers when needed. Revision control will be critical, and can help businesses switch out materials for other alternatives when needed.

- Most importantly, ERP software generates insightful reports that allow you to analyse your successes and failures. These help you to look back on any segment of your supply chain, and make improvements to prevent large-scale disruption.

Businesses Must Learn How To Mitigate Supply Chain Disruptions

As COVID-19 spreads, supply chains will continue to be disrupted. Even as one part of the world recovers, another part might be affected. Supply chains will be shifting and moving, some permanently as businesses close or go online.

This virus has been a test of businesses’ ability to stay resilient when hit by a storm of global magnitude. Business owners like yourself will require all the help they can get to make the best decisions and contain the impact to their company.

You'll also need to prepare for "black swan" events that might happen in the future, and to ensure that they minimise the possibility of supply chain disruptions again.

We've talked about how implementing an ERP software can help your business build an agile supply chain to prepare against future disruptions, but how should you get started in the first place? We've got a winning formula to help you do just that, which you can get by clicking on the image below.