If you’re the owner of a light industrial business, your employees probably spend a fair amount of time on inventory management.

Maintaining inventory at the right levels isn’t just challenging. It can be time and resource intensive. And it might be a drag on your business’s productivity.

If you're looking to optimise your inventory management techniques, we'll help you get started with these four actionable inventory management tips.

Inventory Management for Small Business: Best Practices

1. Advanced Analytics

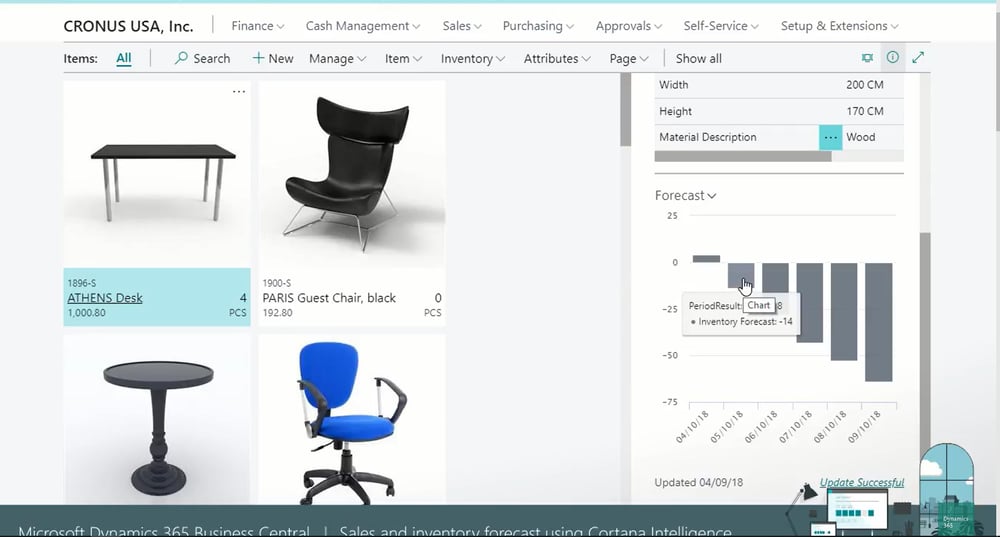

Cortana Intelligence translates raw data into actionable insights, such as this inventory forecast chart. Screenshot courtesy of Microsoft.

Business Central includes data analytics tools from the get-go. It’s fully integrated with Cortana Intelligence, Microsoft’s Cloud-based set of advanced analytics, big data, and business intelligence (BI) tools.

Cortana Intelligence can calculate inventory and sales forecasts, based on historical trends. A simple chart shows you when exactly your stock will be depleted. Or the expected number of units that’ll be sold three months down the road.

If you need to have an item in stock by a certain date, Business Central can also calculate when exactly you should order it to ensure you get it in time.

Maintaining the right amount of stock on hand is now easier, because Cortana Intelligence does the number crunching for you. And you won’t have to rely on guesswork for essential decisions.

2. End-to-end Item Tracking

Business Central includes a comprehensive item tracker, empowering you to offer improved quality assurance and customer service.

It’s capable of end-to-end tracing, down to batches with specific lot and serial numbers.

Users also get a view of availability data by lot and serial number, reducing the risk of double allocations.

If you work with perishables, you can assign expiry dates and rules, lot by lot and item by item. In the same vein, you can also assign warranties to specific lot and serial numbers.

In the event of a recall, a faulty component can be traced back to a specific lot.

You can also trace instances of recalled items in open sales orders, to avoid shipping defective products out.

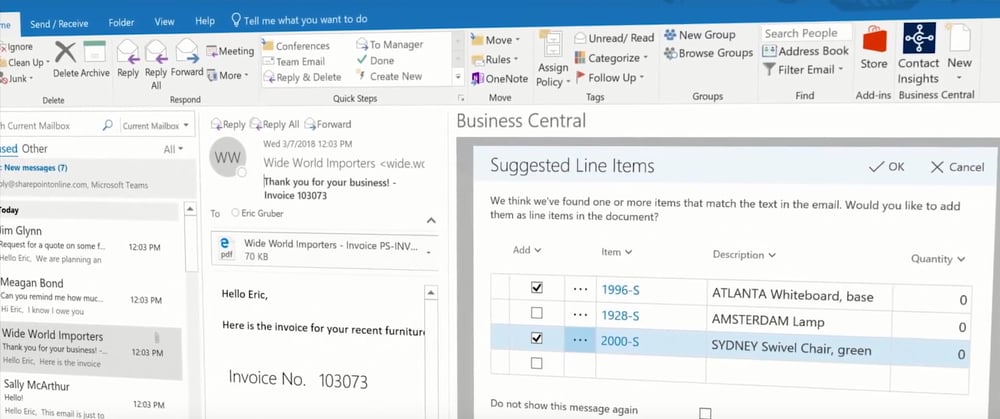

3. Automated Recurring Purchase Order (PO) Generation

You can fill in the details of recurring purchase orders with the click of a mouse. Simply define these details, such as order quantity, model number, and so on. So, the next time a purchase is made, the PO will be ready to go almost immediately.

4. Inventory Costing Management

Business Central collates all your business data in one place. So, you can compare sales and inventory costing data side-by-side to get the full picture.

Let’s go back to the scenario we described above. You notice that sales of model A are below expectations. With costing data on hand, you realise you should reduce output to avoid holding dead stock.

Effective Inventory Management with Microsoft Dynamics 365 Business Central

In this article, you’ll have gotten a practical overview of improved inventory management with Business Central.

You’ve read about:

- The powerful built-in analytics tool that empowers you to make more informed decisions.

- Improved end-to-end visibility, so you can get a complete overview of your business’s performance.

- And the automation of manual work processes, to boost employee productivity.

Want to understand how these improvements can apply to your own business? Drop us a note here and a technical consultant will be in touch shortly.

.png)