It’s no secret Singaporeans love food with a passion.

Or how that passion turns even more fervent during festive seasons.

Last Chinese New Year’s F&B sales in Singapore saw a 5 % increase from the previous year – ringing in the tills at a whopping S$726 million.

But even as Chinese New Year presents huge opportunities for F&B small and midsize enterprises (SMEs) in Singapore, the converse is also true.

Without proper preparations, your F&B company could actually be making losses in areas like:

- Revenue because your supply chain wasn’t equipped to meet the surge in demand

- Opportunities that were stolen by better-prepared competitors

- Dissatisfied customers/vendors because you failed to meet their expectations – even after Chinese New Year ends

- Unhappy employees who work over-time or alongside less competent part-timers

- Inventory wastage or stock-outs due to poor inventory planning

- PR or branding mishaps due to any of the above

It's no wonder then, that many F&B SMEs in Singapore share a love-hate relationship with the festive season.

So how can you ensure your F&B business joins the successful ranks during busy seasons like Chinese New Year?

A recent food and technology publication by The SME Series featured several highly successful homegrown F&B brands, like The Soup Spoon, Huber's Butchery, and more.

(Fun fact: Did you know that The Soup Spoon, Huber's Butchery, P.S. Cafe, Old Chang Kee, Mr Bean Singapore and more, are our ERP customers?)

A quick review of their articles showed that successful F&B SMEs in Singapore generally share one characteristic:

They invested (and are still investing) in their technology and people.

This sentiment is echoed by Kee Ai Nah, executive director of Enterprise Singapore's Lifestyle & Consumer Cluster:

"With the push towards a higher degree of automation, the jobs in food manufacturing have changed, many from manual and laborious tasks to less strenuous human complements to technology."

- Kee Ai Nah, in The SME Series

Because we’re an enterprise resource planning (ERP) consultancy, it wouldn’t be appropriate for us to share tips on improving employee management.

(We’re just a bunch of IT and finance specialists after all. Our expertise is not in HR-related issues.)

Instead, here are several ways you can improve your F&B inventory management and reporting, by using best practices made possible by modern ERP systems.

1. Boost Visibility and Control Over Production Cycle Through ERP Software's Production Modules

Production times are notoriously longer during Chinese New Year, thanks to labour shortages.

There are also the annual surges in orders before and after the holiday season (e.g. order backlog) that need to be managed effectively.

With so many moving parts involved throughout production, success lies in staying on top of your production processes throughout this busy period.

So, here’s a quick self-check. Is your company able to:

- Quickly track and accurately report on your production’s work-in-process (WIP) statuses

- Get precise, real-time views of where your production runs stand, and available capacity for machines, labour etc.

- Easily build schedules to optimise output, leveraging on material master data that includes multi-level bill-of-materials (BOMs)

- Quickly adjust your production plan where necessary, and route around bottlenecks in real-time

If you’ve answered no to one or more of the above, you could do better with a system that gives you better visibility across your production cycles.

Here's a very basic illustration of how it might work.

Suppose there’s an unexpected shortage. With an ERP system, you have multi-level defined BOMs (sales, assembly, production etc.) that allow you to quickly make substitutions for raw inputs, semi-finished products etc.

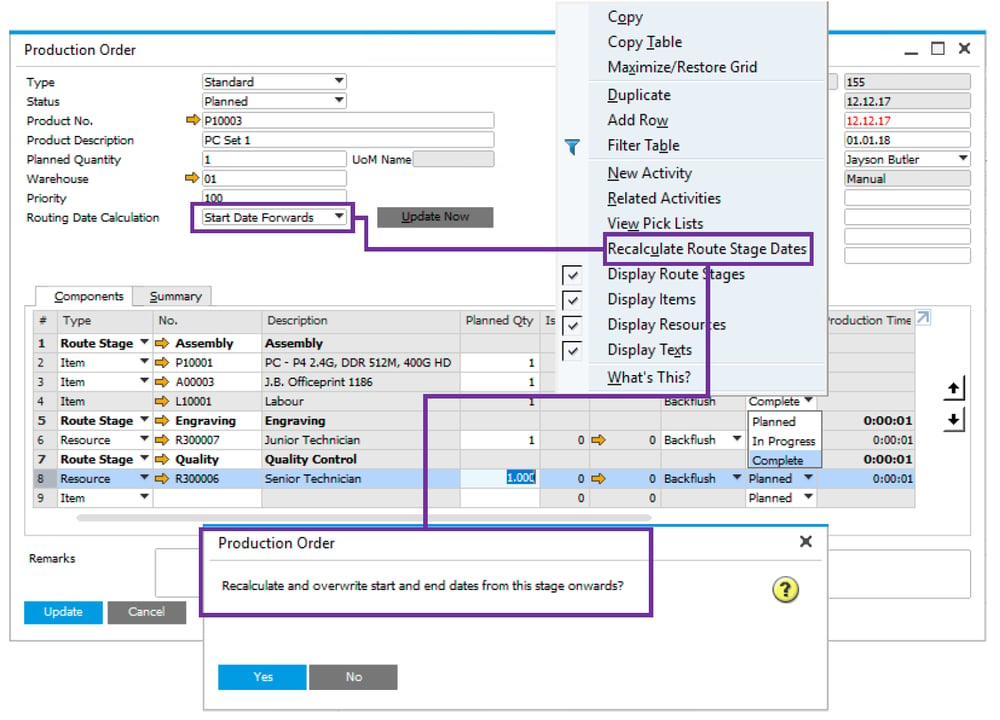

An example of production routing in SAP Business One

An example of production routing in SAP Business One

Built-in functionalities like routings also enable you to easily re-calculate routing dates to reflect your route stage line’s status and more.

You can get these and other production-related functionalities in established ERP systems like SAP Business One, Oracle-NetSuite, or Microsoft Dynamics 365 Business Central.

2. Reduce Stock-Out Situations with Proper Inventory Management and Order Prioritisation Using ERP System's Inventory Modules

If inventory management’s one of your top worries during Chinese New Year, you’re not alone.

One Singapore Productivity Centre study showed that inventory management issues are among the top concerns of Singapore F&B businesses, ranking second to long customer waiting times.

You might even find following scenario familiar:

- You make an educated guess about this year’s Chinese New Year demand, based on past trends

- Send ‘guess-timated’ orders to your suppliers, aiming to get enough to tide over Q1 (or at least the Chinese New Year period, depending on item perishability)

- Chase your suppliers for assurance they’ll meet the promised timelines

- Check and double-check your warehouses, hoping your goods are in the right quantities and locations

Striking that fine balance between having enough inventory to meet orders vs. tying up capital in inventory that doesn’t move isn’t easy. This requires having robust systems and processes in place.

Let’s use a typical SKU as an example of how order prioritisation can be done easily within an ERP system.

Priority is given on a chronological basis i.e. today’s demand is a higher priority than next week’s demand. On top of that, the system will consider which demand type should be fulfilled first (the same applies to supply sources).

It’ll also consider the order’s current state in the process – like warehouse activities, sales or assembly statuses etc.

You can either manually pre-configure these order priorities in your system, or in the case of Microsoft Dynamics 365 Business Central, do so with Cortana Intelligence, its built-in artificial intelligence (AI).

Video clip on how Cortana helps manage inventory in Business Central

Business Central’s inventory management features can predict stock-outs months in advance, helping you find that sweet spot between wastage and stock-out which keeps your business profitable and efficient.

Your stock levels can be updated automatically too. This helps to streamline and automate your inventory management of perishables and other items.

In addition, you can access your inventory data on a mobile device from anywhere, which can be very useful when stocking up.

3. Manage Inevitable Logistical Delays More Effectively with ERP Software

Whether you’re a small local dealer or a large global supplier, Chinese New Year presents unique challenges for managing delivery times and logistics costs – especially if you’ve partners in China.

Common logistics challenges include:

- Shortage of ‘blue-collar’ workers throughout the supply chain

- Especially a shortage of lorry/truck drivers, which can increase waiting times and transport costs

- Rise in freight rates weeks before and after Chinese New Year

- Port congestion and loading/unloading delays, especially in China’s port cities

Herein lies the CNY problem: shipping, trucking etc. delays are often beyond your control. But customers don't care what happens at your end; they only want to see their orders arrive on time. Large corporate customers may even impose penalties on your business for not meeting their expectations during this peak season.

What successful F&B businesses do differently from their peers is they focus on logistical aspects they can control — and do so very well.

With an ERP system in place, you can perform basic inbound and outbound logistics management actions to complement your inventory and financials management.

Actions like expediting outstanding orders, container management, and scheduling specific receipt dates. Or ensuring a smooth progression from your production line / warehouse to your customers, with automated material flows, quality checks, and more.

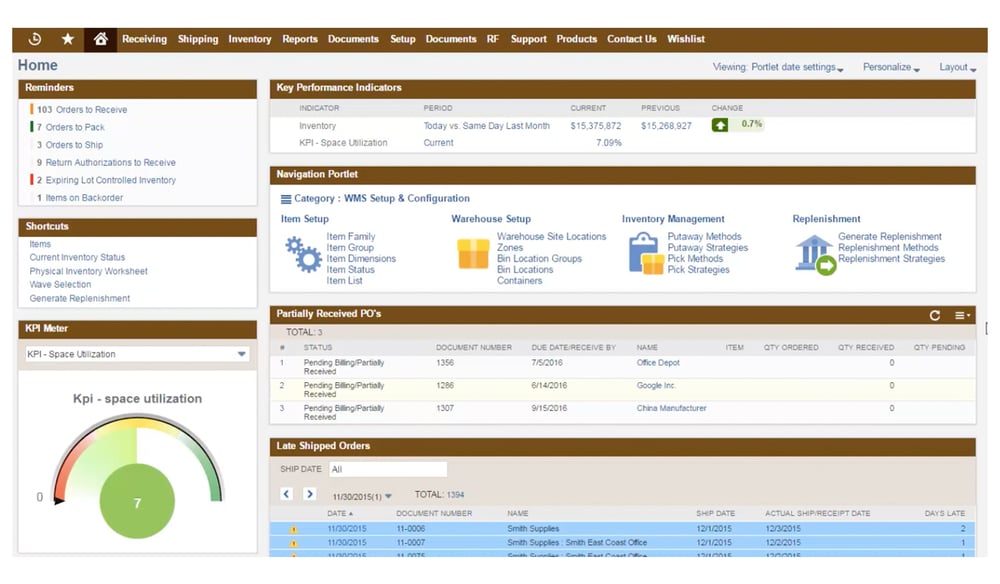

Screenshot of the inbound shipment management dashboard feature in NetSuite, Source: NetSuite

Screenshot of the inbound shipment management dashboard feature in NetSuite, Source: NetSuite

Let's use Oracle-NetSuite as an example. Once your order has been entered and approved (regardless of whether it went through a complex workflow or not), your shipper will be automatically notified.

From there, you can head directly to fulfillment. Alternatively, you could also choose a pick, pack and ship process based on pre-defined preferred picking strategies.

Thinking Ahead for Your Next Chinese New Year

In short, successful F&B businesses understand that effectively controlling inventory, fulfillment, and shipping costs are key to navigating through demanding peak seasons.

By using built-in best practices found in modern ERP systems, you too can optimally manage your resources while minimising the overall total cost of operations.

And quite possibly, leaving you in the best position to say 'Huat a start to the new year!'